Lorünser Austria uses state-of-the-art CNC technology to produce high-quality products in a manufacturing facility covering 5,000 square metres. The quality of the products is crucial for efficient and sustainable power transmission. Low-cost materials with reduced service life or hotspots due to non-planar contact surfaces pose a permanent risk and are a danger point for blackouts.

Lorünser products are made from primary aluminium. Sustainable aspects, such as energy-efficient production, durability and high recycling rate, speak for themselves. Furthermore, primary aluminium guarantees the best transmission values. Lorünser products are additionally subjected to T6 heat treatment. This ensures improvement of the material structure and a reduction in breaks.

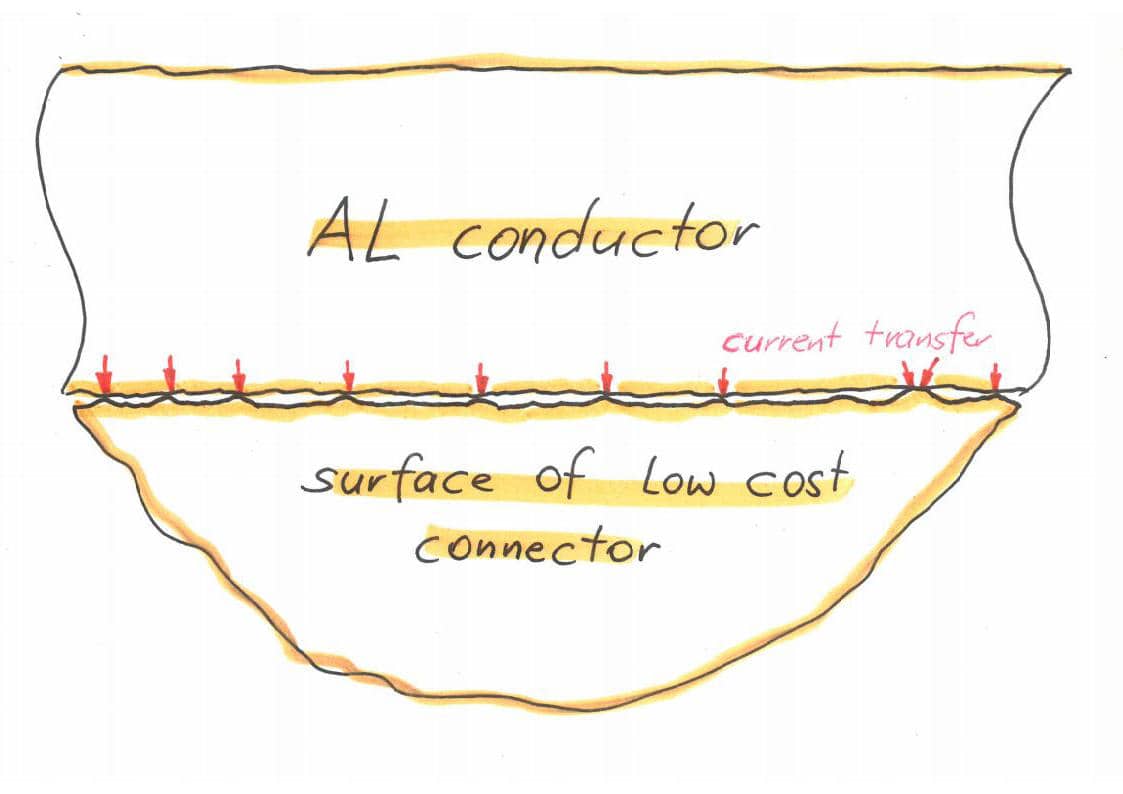

Aluminium is the predominant material in connection technology. In addition to its good electrical conductivity, aluminium also has the property of forming a dense layer of aluminium oxides on bare surfaces.

This oxide layer acts like an insulating layer during power transmission. The result: the resistance is increased and therefore the temperature also increases. If these effects are ignored, this leads to excess temperatures or so-called hotspots and ultimately even to fusing or melting of the connecting elements.

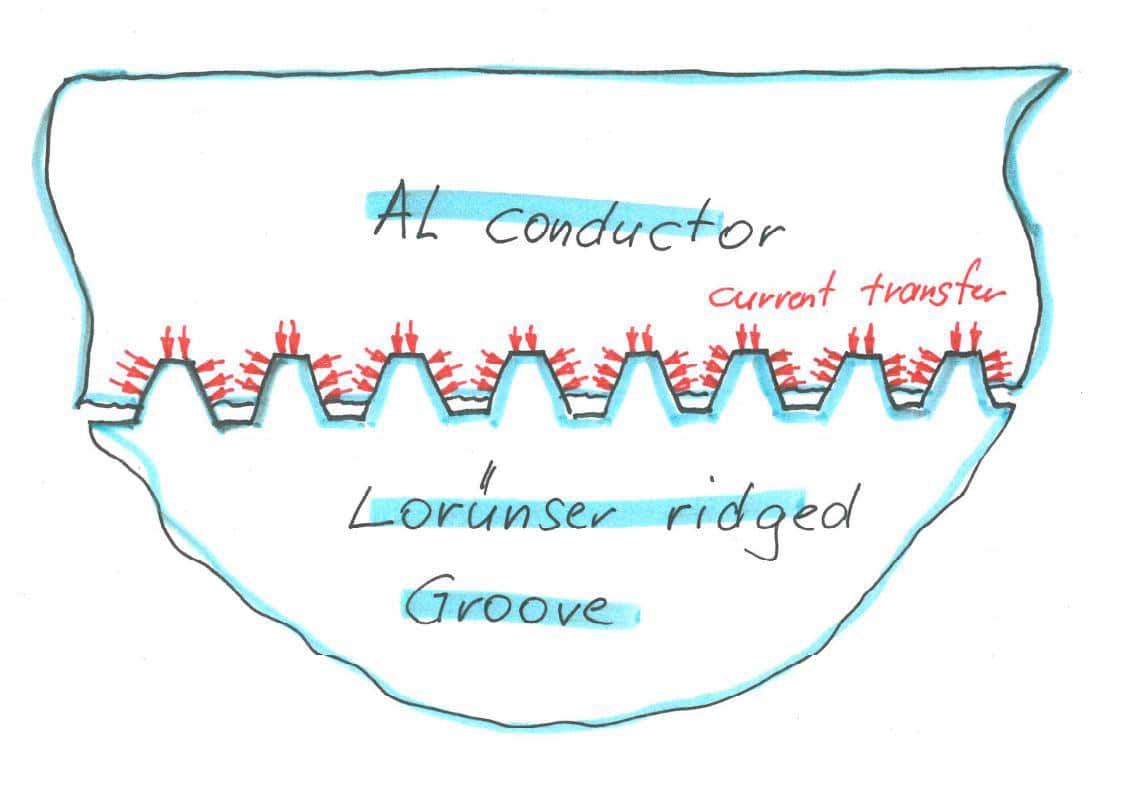

The solution: all contact points of connecting elements should be machined flat. This is the only way to avoid unwanted hotspots which have a major impact on the service life of equipment.

Energy or power transmission takes place at a wide variety of points in a substation. Starting with the transformer via flat connectors and extending to tensioning of the overhead lines via cable connections.

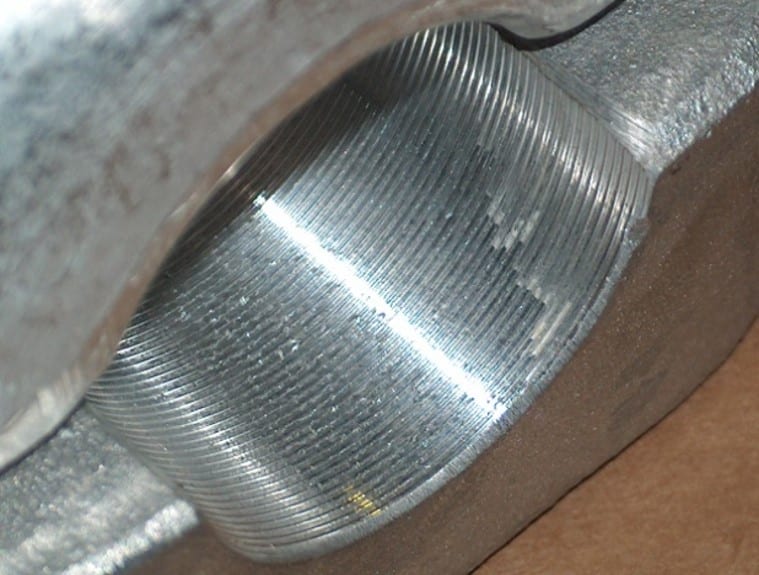

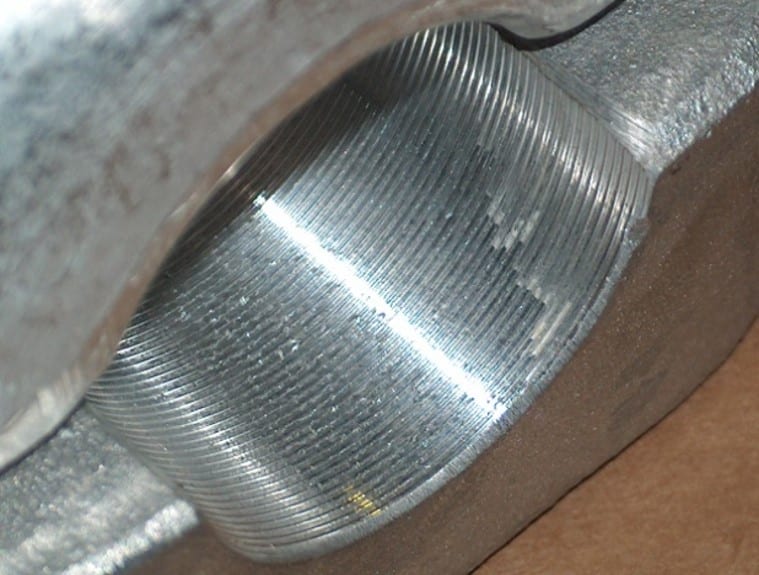

At Lorünser Austria, CNC machines are used to machine all elements for more efficient contact quality. When connecting to aluminium cables, grooved teeth, which ensure that the oxide layer on the aluminium cables is penetrated, are additionally milled into the Lorünser clamps.