Precisely tailored engineering and well-rehearsed teams – highly qualified engineers and technicians take care of the most diverse customer requirements.

We perform a wide variety of calculations from the detailed offer, based on the material list provided, to the preparation of a tender. These include short-circuit calculations, verifications of current-carrying capacity and calculations for the edge strength and deflection of busbars. Furthermore, Lorünser products have internationally recognized test certificates.

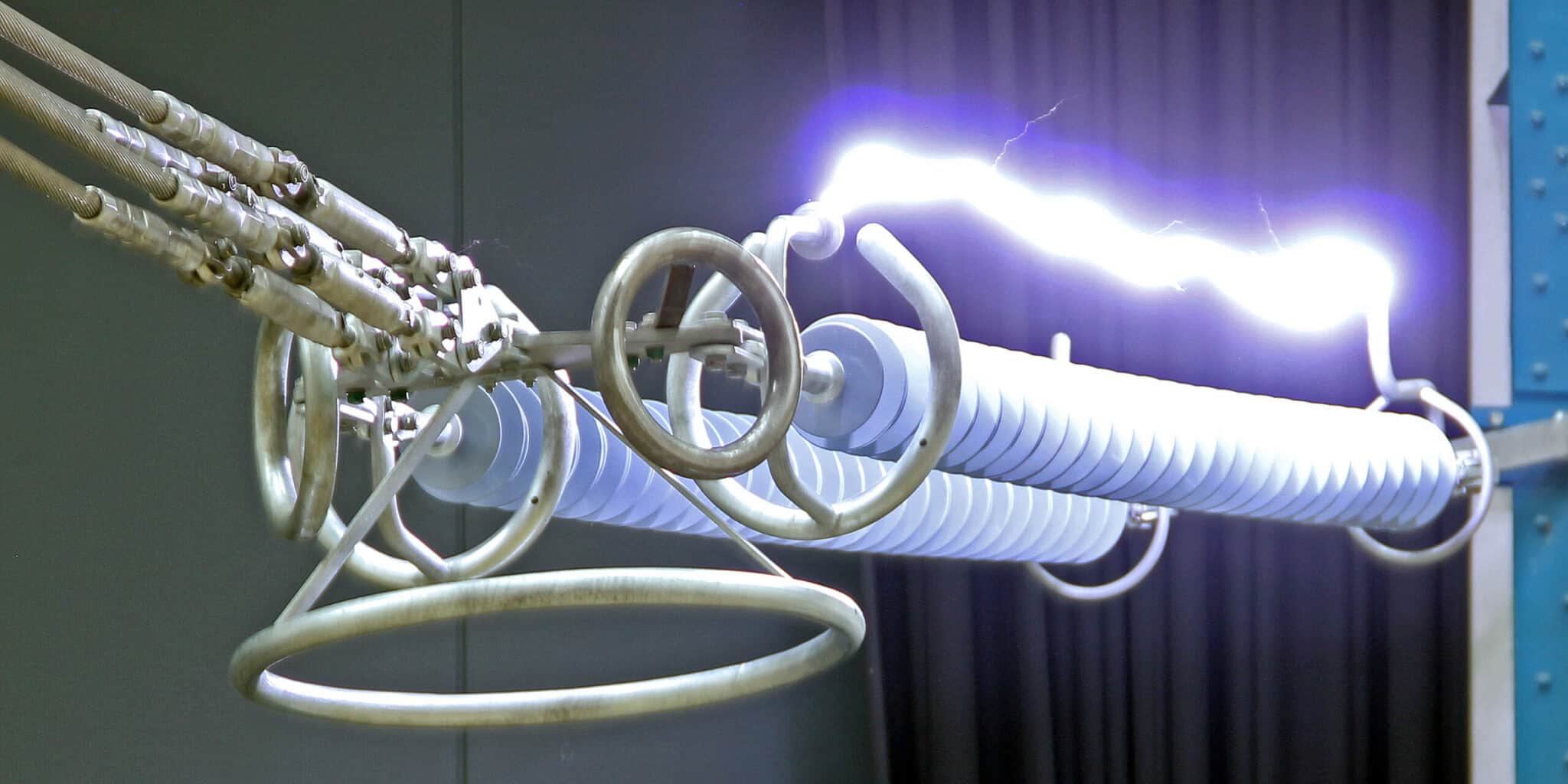

Lorünser Austria simulates the electric field strength in high-voltage components such as tension and suspension strings or clamps for switchgear for its customers. It also uses FEM analysis to check any potential influencing forces on the components.

Products for power plant substations and high-voltage lines have to meet particularly high requirements. Thus, all risks should be determined and eliminated in advance.

Lorünser supports customers with comprehensive analyses of the task at hand and the general requirements, from concept and product development to overall execution of the project. If necessary, it also develops products such as busbar dampers or telescopic joints for specific requirements.

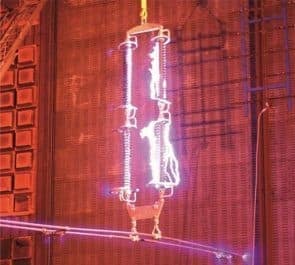

Lorünser’s in-house laboratory can simulate different current loads and record their effects This also includes high-current test submissions. In this case, the temperature characteristic of various products and materials is tested from zero to 12,000 amps. For example, the following are performed:

Other services, such as specific and standardized tests for outdoor components and materials as well as type tests and trials on prototypes can be offered jointly with the support of our partner Mosdorfer, a Knill Group company: