Companies involved in the development and construction of cutting-edge supply infrastructures must not only be broadly positioned, but also have a great deal of expertise and experience. Lorünser Austria’s range of services is correspondingly diverse for many medium and high-voltage technology applications in switchgear up to 1000 kilovolts.

It covers an extensive range of accessories with more than 25,000 products in addition to planning and project management, and complex tasks relating to maintenance and repair. The one-stop supplier concept applies here, meaning that everything for the connection technology comes from a single source.

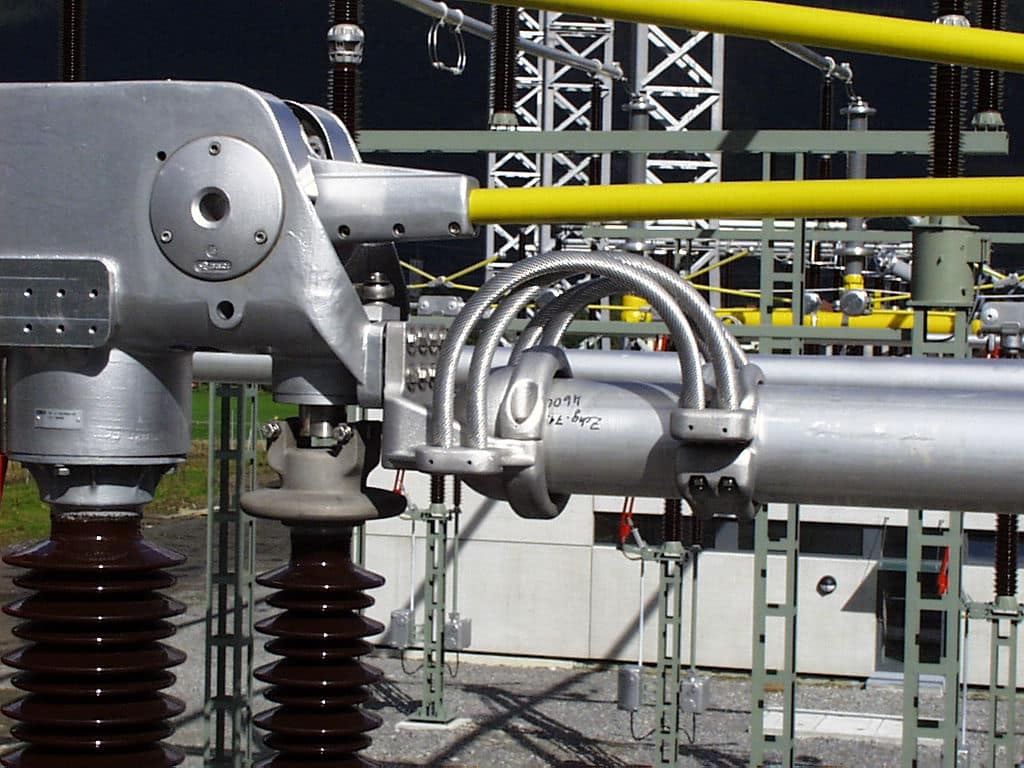

As transmission capacities and voltage levels increase, outdoor substations are increasingly being equipped with tubular busbars. Tubular busbars consist of permanently welded pipes or individual pipes connected by flexible current bridges. This technology has not only proven itself in European outdoor substations, but is now also common practice worldwide.

Tubular busbars have many advantages both technical and economic. They are distinguished by good electrical conductivity, high current-carrying capacity, short-circuit resistance and low weight, and are particularly cost-efficient due to their corrosion resistance and freedom from maintenance. Here, too, Lorünser acts as a complete system supplier under the heading “Everything from a single source”, from deflection calculation to delivery to the construction site and, at the customer’s request, even in numbered packaged quantities depending on the construction phase.

When planning and operating switchgear, the focus is always on operational reliability, thermal stability and the cost effectiveness of transmission.

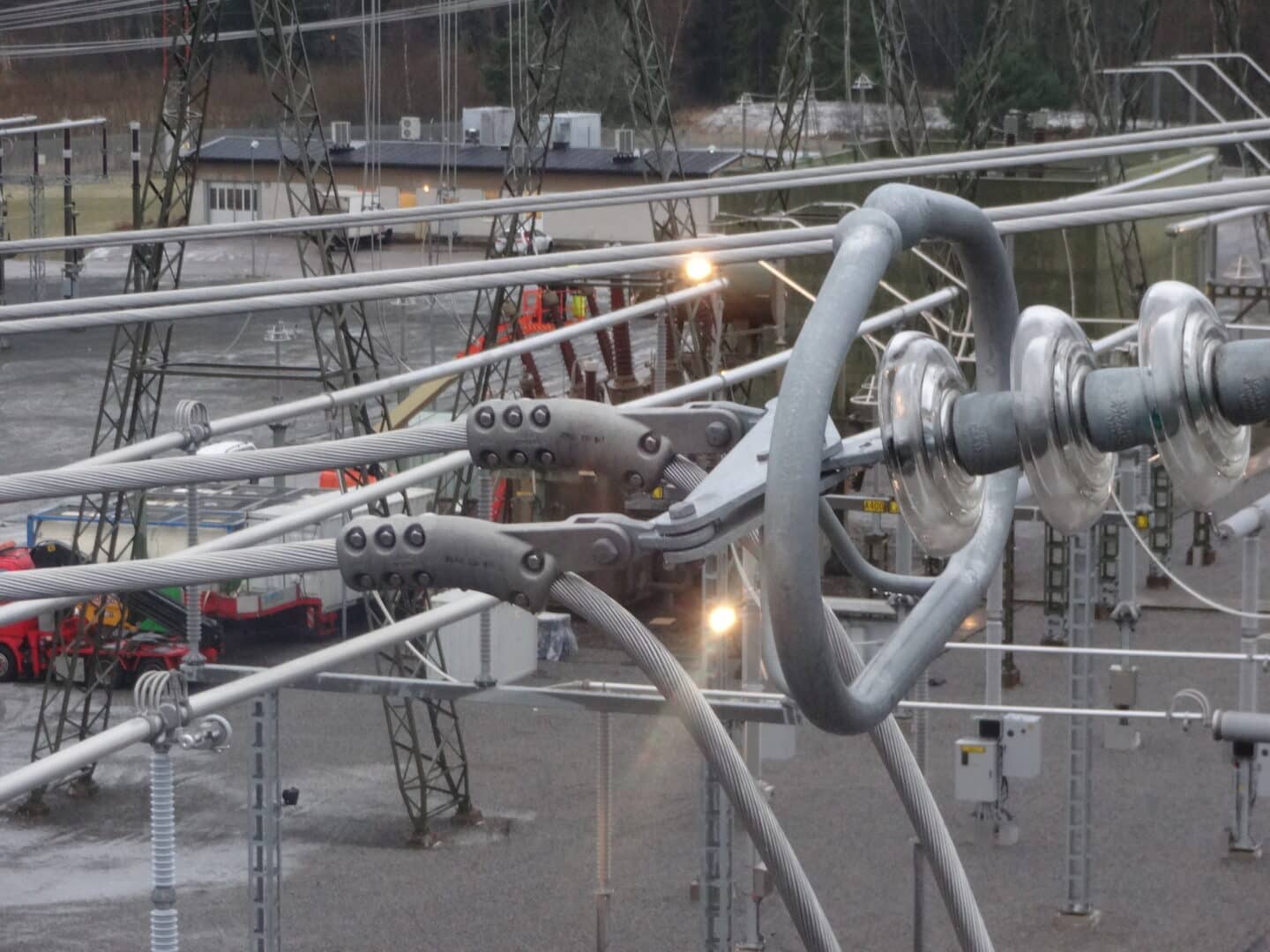

Depending on the application and required conductivity or conductance, Lorünser offers a wide range of transmission line conductors for outdoor substations for many different high-voltage levels, such as high-temperature overhead transmission lines (TAL), aluminium (AAC), Aldrey (AAAC), aluminium-steel (ACSR), copper, AL-Stalum and others.

Lorünser tension strings are in use in more than 100 countries around the world. Depending on the customer’s requirements and specifications, Lorünser engineers use 3D-CAD programs to design detailed suspension and tension strings. We can quickly and easily implement both standardized parts and unusual special requests in our in-house production department. Having our own production facility is a great advantage, precisely because we are able to produce a huge number of design variants due to the many different insulator types, cable types and bundle configurations used.

Lorünser supplies the insulators, which are made of synthetics, such as silicone or glass and porcelain, according to the customer’s requirements. There is no doubt at all that top quality is also paramount here. This is why Lorünser prefers only reputable European suppliers for high-voltage insulators. The crucial advantage for customers is that Lorünser can offer complete solutions in equipment for high-voltage systems and provide the entire chain, consisting of insulators, tension strings, connection elements, corona protection fittings and adjusters.

Power plant substations are exposed to a range of climatic conditions such as wind and weather. Wind, however, is among the biggest challenges. Even light winds create so-called vortices which can cause damage to the tubular busbars. Lorünser offers special busbar dampers for this problem.

Lorünser busbar dampers aim to reduce the energy from vibration, which in the worst case corresponds to the natural frequency, in order to prevent costly damage.